Infrared Thermography

The application of Infrared Thermography in the marine inspection & repair community has never before been as accurate and inexpensive.

Infrared Imaging Applications

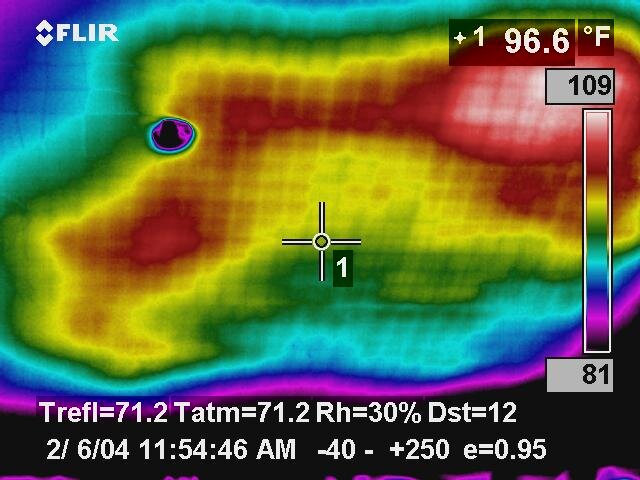

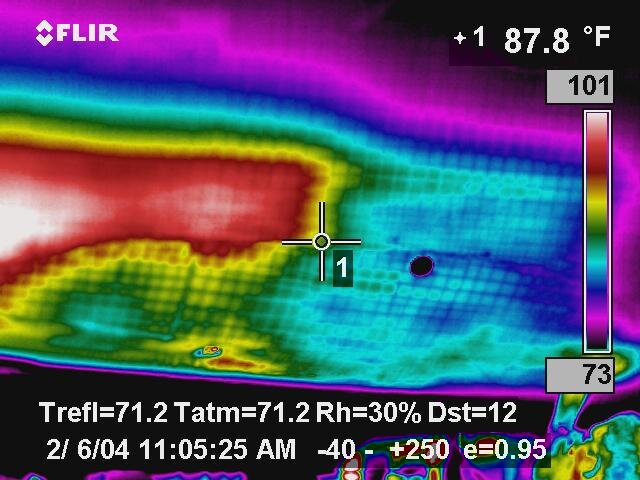

Infrared Inspection avoids costly destructive testing, as well as reassure all parties involved, that all damages have been identified. No longer is there a need to 'start cutting holes' in order to determine the extent of damages. As we've known for years, 'a picture is worth a thousand words.'

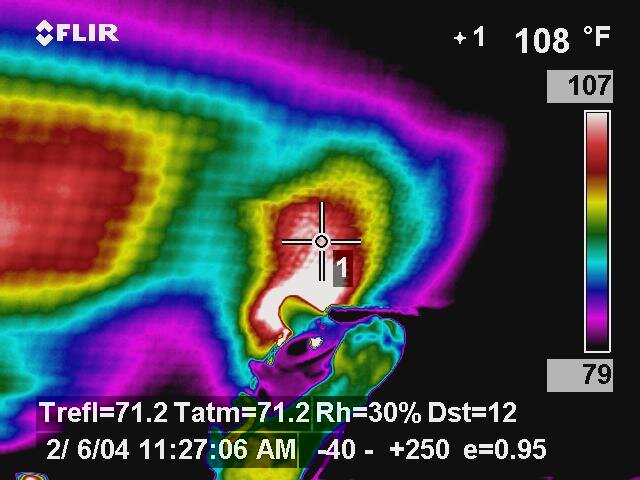

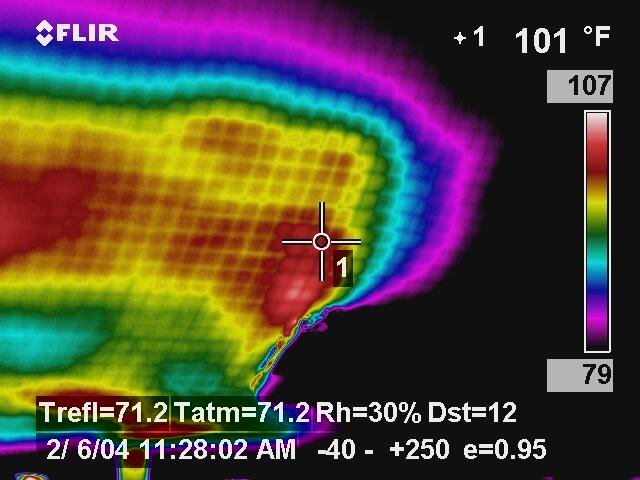

-Grounding & collision damages to fiberglass

-Kevlar & carbonfiber hulls, cored composites including Airex & Balsa, honeycomb, core mat & other core materials

-See into laminates & observe delamination, dis-bonding, breaks, fractures, crushing, voids, blisters & water entrapment

-Carbon fiber mast inspection

-Lightning damage to fiberglass & carbonfiber

-Electrical wiring & breaker/panel inspection

-See "hot" circuits before failure!

-Mechanical engine inspections

-Lubrication features, water & coolant flow, leaking exhaust systems, etc.

The non-destructive nature of Infrared inspection is based on a sensitivity of .035 degree Fahrenheit, FLIR T640 Thermacam the video camera that detects infrared radiation transfer through various materials, then displays the temperature differentials and offers instant still and motion video pictures. The camera is a radiometric device that captures temperature data in every pixel of the image for later analysis.